This post was contributed by a community member. The views expressed here are the author's own.

( 1) Exactly how to make the mold life longer? Shrimp Feed Pellet Machine

With the continual introduction of timber pelletizer device right into the market, the development of mechanical tools is additionally continuously changing. The damage of the mold during the production of wood pellets is likewise a major cost. So, how to preserve it straight influences the service life of the wood pellet making device. Therefore, it additionally straight affects the handling expense of wood pellets. How to make the mold and mildew life of the timber pelletizer device maker much longer? Obtain your solution today!

① Frequently tidy oil and fill

② No need to clean the mold and mildew for a long period of time

③ The mold ought to be stored in a dry and aerated area

④ The taking care of process needs to beware

( 2) Why do the pellets produced by the wood pellets device have a negative appearance?

Why do the pellets created by the wood pellet mill equipment look poor? Today we will figure out why. Throughout the production of wood pellet fuel by the wood pellet manufacturing device, there will certainly be a scenario where the pellets have powder and also have a rough surface area. Currently, it is likewise needed to inspect the equipment information setups of the timber pelletizer device. Besides, what is the reason for this sensation?

Related post: wood pellet maker prices

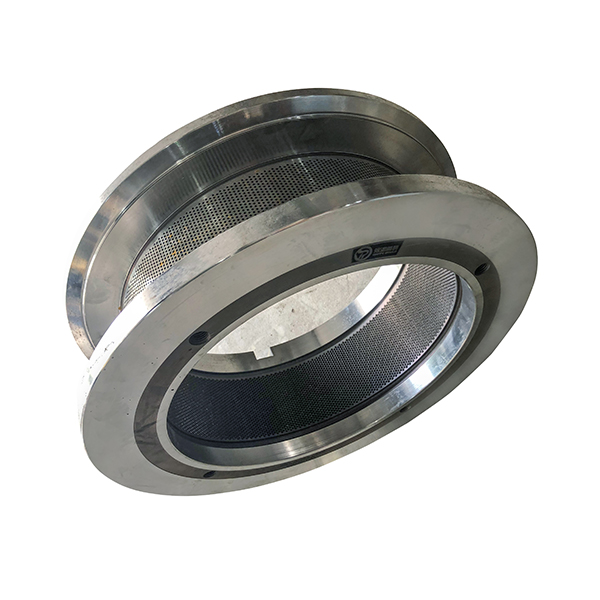

Timber pellets trigger even more wood pellet powders, this feedstock can be caused by low dampness content, the wetness material of timber pellet maker feed is normally between 12% as well as ~ 15%. After changing the dampness web content of the raw material, the issue still exists, that is, the pressure roller die is seriously put on. When the internal surface of the ring die of the wood pelletizer equipment is severely used or the particle size requires to be transformed, it requires to be changed. The surface of the sawdust pellets is rough, which might be brought on by the excessive moisture content of the raw material, or the preliminary use of the mold. This problem can be fixed by adjusting the wetness web content of the raw material, or by repetitively grinding the mold with the product.

Fertilizer Granules Making Machine To sum up, the reasons that the pellets created by the wood pelletizing equipment are not good in look are discussed today. I hope it will certainly aid you when you utilize the timber pellet machine again. Throughout the years, Richi Machinery has actually concentrated on the research and development and also production of wood pelletizer machine machines, biomass pellet makers, sawdust pellet machines, gas pellet devices, timber handling devices, drying out tools, cooling down equipment and product packaging equipment.